Precision Laser Cutting Services

Routing, Sawing & Acrylic Fabrication

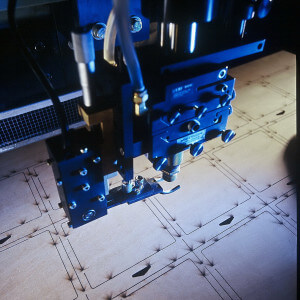

Modernistic has the ability to laser cut many types of materials with intricate cut patterns. In the laser cutting process, a beam of intense light cuts through the substrate. Contact with the material is not needed in the cutting process, however on some substrates it can leave behind a burnt residue. Laser systems include an integrated vacuum table to hold down substrates as the part is being cut. On some materials, the laser can simultaneous edge polish the part to provide a glossy finish. The precision achieved with laser cutting is exact and is well suited when substrates are unable to be die cut due to their rigidity and thickness.

Modernistic has the ability to laser cut many types of materials with intricate cut patterns. In the laser cutting process, a beam of intense light cuts through the substrate. Contact with the material is not needed in the cutting process, however on some substrates it can leave behind a burnt residue. Laser systems include an integrated vacuum table to hold down substrates as the part is being cut. On some materials, the laser can simultaneous edge polish the part to provide a glossy finish. The precision achieved with laser cutting is exact and is well suited when substrates are unable to be die cut due to their rigidity and thickness.

For parts that cannot be laser cut and where edge burning is an objection, Modernistic is equipped with a number of CNC routers which can handle thicker, rigid substrates that cannot be die cut. In addition, Modernistic can rout printed parts with extreme accuracy utilizing a camera to read i-cut marks and adjust the routing pattern to the print. The size capability for these routers is up to a 79” X 120” sheet.

Precision Horizontal Panel Saw

Modernistic has an extremely accurate CNC controlled table saw to cut parts with simple square corners. This saw is adjustable from 0 to 150”, and it cuts up to a 5” lift of a variety of substrates.

Heat Bending / Plastic Bonding / Assembly

Modernistic’s in-house Plastic Fabrication creates 3D innovative displays with impact and appeal. Modernistic has heat bending and plastic bonding capabilities. Common plastics include: PETG, Acrylic, PVC/Rigid Vinyl, Styrene, ABS, Kydex, Polycarbonate. Modernistic designs your displays to exact specifications with our wide range of fabrication capabilities:

- Customized designs and prototyping

- Straight line heat bending up to 10 feet long

- Deburring, edge finishing and polishing

- Plastic bonding / Acrylic Fabrication

- Assembly